- Home

- About us

- Products

- Chainsaw Spare Parts

- Brush Cutter Spare Parts

- Lawn Mower Spare Parts

- Small 4 Stroke Engine Spare Parts

- Generator Spare Parts

- Water Pump Spare Parts

- Rotavator and Tiller Parts

- Pressure Washer Spare Parts

- Earth Auger Spare Parts

- Power Sprayer Spare Parts

- Mist Duster Spare Parts

- Hedge Trimmer Spare Parts

- Blower Spare Parts

- Cut-off Saw Spare Parts

- Chainsaw Guide Bars

- Chainsaw Saw Chains

- Brush Cutter Trimmer Heads

- Brush Cutter Trimmer Lines

- Brush Cutter Belts

- Lawn Mower Blades

- Faqs

- News

- Certificate

- Contact us

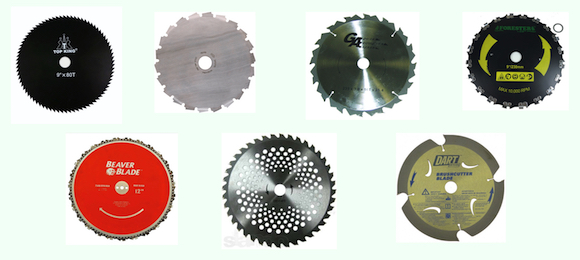

Types of Brush Cutter Blades

time2023/04/08

- Learn about the different types of brushcutter blades and the pros and cons of each to help you make an informed decision when buying new blades for your brushcutter or lawnmower.

Learn about the different types of brushcutter blades and the pros and cons of each to help you make an informed decision when buying new blades for your brushcutter or lawnmower.

There are basically four types of brush cutter blades; knife, chisel, smasher, and mulching. The following is a detailed introduction to the advantages and disadvantages of different types of brush cutter knives.

Knife

These types of blades have a sharp edge on the leading edge of the blade and are cut by cutting through vegetation. It is by far the most common type of metal blade and is usually standard on brush cutters with metal blades. Blades come in an almost infinite number of shapes, but what they all have in common is that they are usually lasered or stamped from sheet steel. They range in shape from oblong to round and have dozens of small knife-like teeth. The most common is a star with three or four cutting edges.

Advantage

Inexpensive, due to being made from one piece and stamped from sheet steel for faster production. Usually good at cutting soft materials such as grass and waterweed. But it depends a lot on the design of the blade. Depending on the design and quality of the steel, there is usually a lot of punishment to take.

Shortcoming

As the tip of the blade becomes blunt, the efficiency decreases rapidly. This is because the blade spins so fast that only the tip of the blade can make the cut. When the brushcutter head is oscillating rapidly from side to side, the cutting edge of the blade will actually do nothing but cut. As a fixed blade, when you hit hidden rocks or steel objects, the tip will bend or chip, depending on the type of blade and the quality of the steel. This is why some three of the four blades have beveled cutting edges. Not for cutting efficiency, but for liability reasons to make the blade more resistant to breaking.

Cutting Ability

The number of blades does have a big impact on how the blade behaves. The blade relies on the sharp leading edge of the blade to cut, but since the blade rotates at around 100 to 120 revolutions per second, usually only the outermost edge does the cutting.

Now, if you can imagine your mower head oscillating from side to side, the speed of the oscillating motion will determine how much the blade is exposed to the new grass. The swing is very slow, and only the tip of the blade can make the cut. Swing very fast, more tips mow.

Now consider a rectangular blade with two cutting edges, which rotates at 100 revolutions per second, which means that one cutting edge passes the same point 200 times in one second. Let's say you swing the brushcutter sideways 1 meter in 1 second. This means that only the outside 5mm of the blade can actually cut new material. With the 4-edged blade, only a 2.5mm outer edge cuts, while the 8-edged blade only cuts through any grass with a 1.2mm outer edge.

So as you can see, the blade doesn't actually do any cutting. Now moving on to the 40-point blades, each cutting only a fraction of a millimeter. So, as with nylon wire, only the outermost end of the blade actually does the cutting.

This little blade dulls quickly, so it ends up shredding vegetation, which means the blade quickly becomes a shredding blade. Only when this happens and rough uncut vegetation springs back under the blade, or when cutting in a vertical motion, will the inner blade make any cut? Dull blades are one of the main reasons users get into the habit of turning their brush cutters up to full speed and throwing the blades into heavier vegetation, a habit that can be hard to break when switching to chisel or saw-type blades.

Multi-tip blades become less effective the faster the tip loosens, but at the same time, due to their more rounded shape, drag grass to the outside of the blade and are therefore less likely to cause long strands of grass to wrap around the gearhead.

This is why different blades are better suited for different types of vegetation, and why many brush cutters come standard with a range of blades.

Mulching Ability

Likewise, rectangular and star-edged blades are best for mulching when the blade is cutting vertically through vegetation, as these provide the largest cutting edge area for vegetation.

A more rounded shape, multi-point blade with a shorter blade is of little use when it comes to mulching.

Chisel Blades

These types of blades have a sharp tooth on the perimeter of the blade and cut by gouging or scraping through vegetation. All of these blades are round with varying numbers of teeth around the perimeter. These teeth can be part of the blade and have a curved offset for blade clearance, or have a chainsaw-style blade that is either riveted to the disc or the actual chainsaw blade is riveted in two circles between plates. Most are now tungsten bits, as the price of these blades has dropped significantly over the years.

Advantage

Cutting is more efficient because the cutting edge is on the outside, where it actually makes contact with the material being cut. Excellent at cutting tough materials such as woody weeds and hardwoods.

Shortcoming

Usually more expensive because they are more complex shapes and require additional machining to bend, grind or attach additional parts. Since the cutting edge is at the tip, it is subject to more impact and abrasion damage.

These types of blades require sharp teeth to cut effectively and are often thrown away. Since many of these types of blades are difficult or even impossible to sharpen by the average user.

The deeper the cut, the more likely the blade will bite in and kick one way or another. The more teeth the blade has, the farther the blade will kick as it tries to use up the slot.

The deeper the cut, the more careful you have to be to keep the blade straight, twisting it one way or another can cause the blade to get stuck in the cut groove, causing severe kickback.

Cutting Ability

Most of these types of blades are very good at cutting horizontally, up to the maximum depth it can cut. Generally, when cutting branches with a diameter larger than 50-60mm, the cutting speed will slow down quickly.

This is because most brush cutters are designed for wire cutting, nylon wire requires high tip speeds to cut through vegetation, and they are not as good for high torque as chainsaws. With multi-tooth saw blades, the deeper the cut, the more teeth will be cut and the greater the resistance. This means they require more power and torque to drive and are therefore better suited for larger machines.

The biggest problem with circular saw blades when you're cutting larger diameter branches is that you have an increasing number of teeth, all cutting at slightly different speeds and depths. This is due to the rotation of the blade and the direction the blade moves. So when the blade moves in the direction of cutting the branch, some of the teeth cut into the direction of travel and cut into the wood. As some teeth cut through the wood, some teeth go against the direction of travel and cut out of the wood. This means that as the cut gets deeper, the chance of the blade being kicked in one direction or another increase to the point where it becomes difficult to control the blade.

Unlike bench or skill saws, the teeth cut in the direction of travel and drag material across the table to prevent work from bouncing.

Coverage Ability

These types of blades are usually poor at mulching because of the large discs, which are not easy to move up and down the bushes.

Smasher Blades

These types of blades have no sharp edges and typically rely on the thin thickness and weight of a rotating blade or chain to shred vegetation. These are usually rotating flail-type blades, connecting metal blades, and a range of different types of chains.

However, due to EU directives that non-manufacturer-spec blades can be fitted to brush cutters in EU member states, many blades are no longer available, which is probably a good thing. I'm guessing here, but I think many one-piece knife blades if the edge wears out at all, end up as shredding blades.

Advantage

Maintains its collective design efficiency without maintaining any advantages.

Typically applied to soft grasses and aquatic weeds.

Shortcoming

Usually more expensive since it is made from multiple parts.

Many are not made of suitable materials to withstand extreme loads, so life expectancy is often low.

Generally, it is only effective for grasses and aquatic plants. Prolonged crushing of woody weeds will lead to early failure.

Some, like chain blades, have very high drag and thus consume a lot of power just to maintain a high enough rotational speed to shred vegetation effectively, so are better suited to higher-powered machines.

Cutting Ability

For grass and water plants, this blade is very effective, but try cutting anything harder and you'll end up trying to burn your way. This is because its flail blades don't have enough mass to penetrate denser weeds, so they just keep getting bounced off.

Mulching Ability

This blade is good for mulch and waterweed, anything harder than that and it just has no impact.

Cover Blade

It's designed to shred lawn mowing residue and scatter it back onto the grass, providing nutrients and moisture to the growing grass. This method of shredding lawn litter not only reduces the amount of litter but also improves the quality and appearance of your lawn.

Advantage

Will cover leaves and small twigs well.

Shortcoming

It requires a lot of power to drive, so it is only suitable for large machines.

Again, a lot of impact force is fed back to the brushcutter because they are only suitable for larger brush cutters.

Much material may be thrown with considerable force.

The blade types of brush cutters have been introduced in detail above. If you want to buy brush cutter accessories, please contact us.

Hustil is a professional custom garden tool spare parts manufacturer with 19 years of experience. We provide VIP users with a full range of accessories search and query, garden tool installation and replacement, and after-sales service. More than 10 years of strict compliance, now has more than 300 years of mature supply chain factory production.